In der Welt der elektronischen Schaltungen sind Kondensatoren unverzichtbare Grundbausteine. Zu den vielen Typen – darunter Keramik-, Elektrolyt-, Folien-, Papier-, Glimmer-, Superkondensatoren und Glasurkondensatoren – Mehrschichtige Keramikkondensatoren (MLCCs) Und Folienkondensatoren zeichnen sich durch ihre einzigartigen Eigenschaften und ihre breite Anwendung in verschiedenen Bereichen aus. Das Verständnis der wesentlichen Unterschiede zwischen MLCCs und Folienkondensatoren ist für Ingenieure entscheidend, um optimale Designentscheidungen zu treffen.

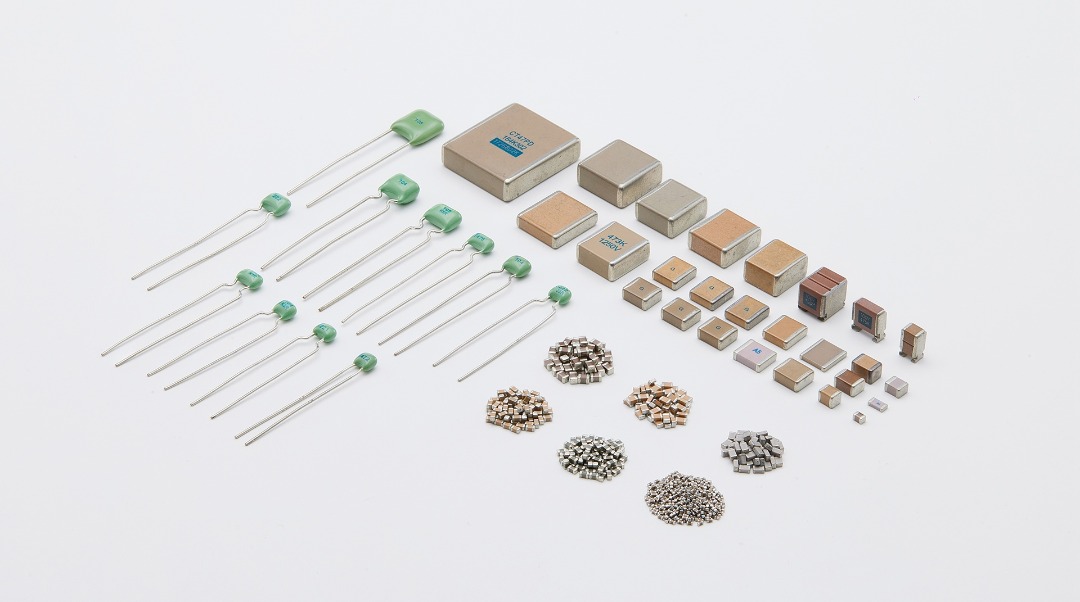

Der offensichtlichste Unterschied ist ihr Aussehen. Doch wie unterscheiden sich MLCCs und Folienkondensatoren hinsichtlich der Designauswahl? Dieser Artikel vergleicht sie hinsichtlich Abmessungen, Materialien, Leistung und Anwendungen, um ihre Besonderheiten und zukünftigen Trends hervorzuheben.

1. Materialzusammensetzung

MLCCs: Verwenden keramische Materialien wie Bariumtitanat (BaTiO₃) als Dielektrikum. Diese Keramiken bieten hohe Dielektrizitätskonstanten und ermöglichen so relativ große Kapazitätswerte bei kleinem Volumen.

Folienkondensatoren: Sie verwenden Kunststofffolien wie biaxial orientiertes Polypropylen (BOPP) oder Polyimid (PI) als Dielektrikum. Elektroden werden durch Metallisierung (Metalldampfabscheidung) auf der Folienoberfläche gebildet.

2. Größe und Formfaktor

MLCCs: Bieten einen erheblichen Vorteil bei der Miniaturisierung. Gängige Gehäusegrößen reichen von winzigen 01005 (0,25 mm x 0,125 mm) bis hin zu 2220 und mehr. Dadurch eignen sie sich ideal für hochdichte Leiterplatten in kompakten Geräten wie Smartphones und Tablets.

Folienkondensatoren: Aufgrund ihres Herstellungsverfahrens und ihrer Struktur sind sie im Allgemeinen größer. Das Erreichen der Mikrogröße von MLCCs ist eine Herausforderung. Ihre Größe ist jedoch weniger entscheidend in Anwendungen, bei denen die Leistung wichtiger ist als die Miniaturisierungsanforderungen, wie beispielsweise in der Leistungselektronik.

3. Anwendungsgebiete

MLCCs: Hervorragend geeignet für Anwendungen, die gute Hochfrequenzeigenschaften erfordern. Sie finden sich häufig in HF-Schaltungen, digitalen Hochgeschwindigkeitsschaltungen, der Signalverarbeitung und in der Stromversorgungsfilterung von Unterhaltungselektronik wie Telefonen und Computern.

Folienkondensatoren: Sie überzeugen in Hochspannungs- und Hochleistungsszenarien dank ihrer hohen Nennspannung, ihres geringen Verlustfaktors und ihrer Selbstheilungsfähigkeit. Typische Anwendungen sind Wechselrichter für Fahrzeuge mit alternativem Antrieb (NEVs), Blindleistungskompensationssysteme in Stromnetzen und Frequenzweichen in Hi-Fi-Audiogeräten.

4. Leistung: Vorteile & Nachteile

MLCCs:

Vorteile: Sehr kleine Größe, niedrige Kosten, Eignung für die Massenproduktion, gute Temperaturstabilität (für bestimmte Typen wie X7R, C0G/NP0), wie z. B. SMD-Mehrschicht-Keramik-Chipkondensator der Torch CC41-Serie.

Nachteile: Höhere Kapazitätswerte erfordern deutlich größere Abmessungen. Anfällig für thermische Ausfälle bei hohen Welligkeitsströmen. Anfällig für Mikrorisse (mechanische Spannungsbrüche), die Zuverlässigkeit und Lebensdauer beeinträchtigen. Piezoelektrische Effekte können hörbare Geräusche (akustische Mikrofonie) verursachen.

Folienkondensatoren:

Vorteile: Hohe Präzision, hervorragende Langzeitstabilität, sehr geringe Verluste (hoher Q-Faktor), hohe Spannungsfestigkeit, inhärente Selbstheilungsfähigkeit.

Nachteile: Komplexerer Herstellungsprozess führt zu höheren Kosten. Sehr kleine Größen sind schwer zu erreichen.

Gemeinsamkeiten:

Trotz ihrer Unterschiede haben MLCCs und Folienkondensatoren die gleiche Kernfunktion wie Kondensatoren: Sie blockieren Gleichstrom und leiten Wechselstrom weiter. Sie speichern und geben elektrische Energie ab und ermöglichen so wichtige Schaltungsfunktionen wie Filterung, Kopplung, Entkopplung und Resonanz.

Wie wählen Sie aus? Wichtige Überlegungen für Designer

Frequenz: Für Hochfrequenzschaltungen sollten MLCCs bevorzugt werden. Für niedrigere Frequenzen eignen sich Folienkondensatoren.

Präzision und Stabilität: Wenn hohe Präzision und Langzeitstabilität entscheidend sind, sind Folienkondensatoren die bessere Wahl. Wenn der Kostenfaktor den Bedarf an höchster Präzision übersteigt, bieten MLCCs ein besseres Preis-Leistungs-Verhältnis.

Spannung: In Hochspannungsumgebungen ist die hohe Spannungsfestigkeit von Folienkondensatoren ein großer Vorteil.

Platzbeschränkungen: Bei platzbeschränkten, miniaturisierten Designs ist die geringe Größe der MLCCs von größter Bedeutung.

Kosten: MLCCs haben im Allgemeinen einen erheblichen Kostenvorteil, insbesondere bei Anwendungen mit hohem Volumen.

Abschluss

MLCCs und Folienkondensatoren unterscheiden sich deutlich hinsichtlich Material, Größe, Leistung und primären Anwendungsbereichen und bieten jeweils spezifische Vorteile und Nachteile. Beim Schaltungsdesign müssen Ingenieure die spezifischen Anforderungen – einschließlich Frequenzbereich, Spannungspegel, Präzisionsanforderungen, Kostenziele und Platzbeschränkungen – sorgfältig prüfen, um die Vor- und Nachteile der beiden Kondensatortechnologien abzuwägen. Die optimale Wahl gewährleistet eine maximale Schaltungsleistung und trägt zur kontinuierlichen Weiterentwicklung elektronischer Geräte hin zu höherer Leistung, größerer Miniaturisierung und geringeren Kosten bei.